Biotechnology has led to breakthroughs in many areas of modern industry. From new products and the sophisticated use of raw materials, but also to more efficient and environmentally friendly production of existing products with traditional material choices. In addition, a more stable quality can be achieved through controlled, repeatable bioreactor processes.

In addition to the pharmaceutical industry, bioprocesses are also used to produce fuels in the pursuit of more environmentally friendly fuel alternatives.

In fermentation processes where the biocatalytic effect of enzymes is used, pharmaceutical or chemically active ingredients are produced more efficiently under controlled forms with high accuracy.

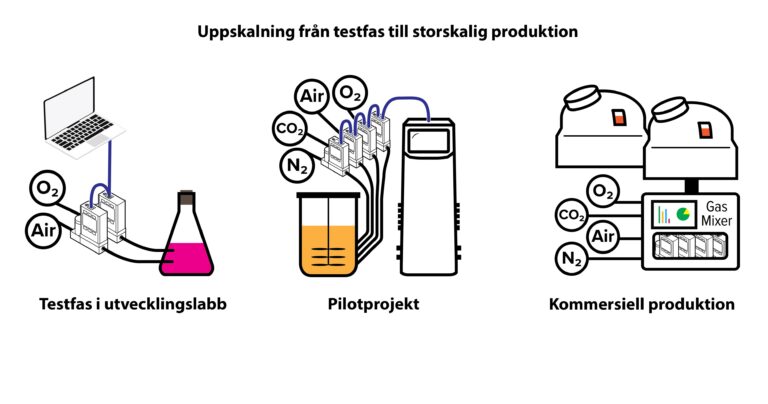

The development of laboratory processes towards industrial scale must be consistent. The management of these large-scale processes must not only lead to a good and high-quality final product, but also achieve cost efficiency on the way there. Assessment of operating parameters, quantities, dimensions and production times is crucial and must be easily recorded in the laboratory. With the right instrumentation, very small flows and dosing quantities can be monitored and distributed exactly in R&D laboratories and in prototype constructions for pilot projects.

Large-scale production facilities must be built with a view to saving both space and costs. Therefore, the number of instruments and production lines needs to be minimized. It is then crucial that measuring instruments are used that have a wide measuring range so that one and the same instrument can meet different production needs.

In flow measurement technology, this is often problematic since many measuring instruments on the market have a limitation in the lower measuring range with unacceptable accuracy levels as a result.

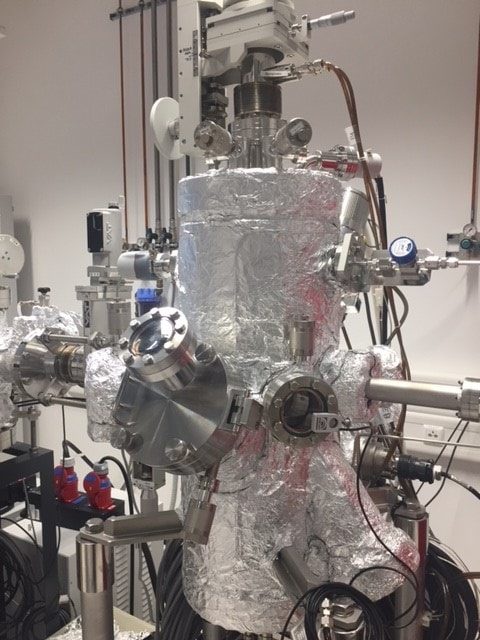

Another important point in bioprocessing is the material requirements for all technical components. Contamination of sensitive bioreactor environments needs to be prevented, which is why high-quality materials, especially seals, must be used in these processes.

In addition, equipment and pipes in bioprocesses are often exposed to "back flow" of system moisture and should therefore not be damaged by it.

Another key factor for cost-effective production of bioprocess materials is the flexibility of the instruments to cope with changes in application factors as the producer's product range changes. Processes must be adapted to new product and customer requirements. Of course, existing equipment, including measuring and control instruments, should be able to be used further without the need to be sent to the manufacturer for modification.

Because of these requirements, conventional / thermal mass flow meters and controllers are often not suitable for use in bioprocesses. Alternatively, they are very expensive because more instruments are required to be used to meet the need for flexibility.

Flow measurement and flow control for bioprocesses

Alicat Scientific has a model series of mass flow instruments with mass flow meters and mass flow controllers adapted for the bioprocess industry. This model series delivers exactly what biotechnologists and developers need with significantly better precision and cost-effectiveness.

The Alicat BIO series offers 2000:1 resolution, which often means fewer instruments to measure and control/regulate all the flow ranges required for different gases with high and low flow requirements in a system. Accuracy for these instruments is an impressive +/- 0.5% of reading or +/- 0.1% of full scale. Compared to previous instruments, this accuracy is a ground-breaking improvement.

With ultra-fast response times of only 10 ms and the possibility of fast communication protocols such as EtherCAT or EtherNet/IP interfaces, the BIO series is ideal for Pharma 4.0.

The Alicat mass flow controller is resistant to water and is manufactured only in corrosion-resistant (FDA approved) sealing materials, as well as acid-resistant steel SS 316L in the flow housing and sensors, which are on the ASME recommendation list and do not contaminate the bioreactors.

An ultra-sharp modern color display provides an overview of the process status. In addition, all Alicat BIO instruments have innovative functions such as gas selection and unit selection directly in the display.

This means that any instrument for CO2, air, O2, N2 or more than 100 other gases can be used without sacrificing precision or requiring recalibration. Adaptation to new process requirements is carried out by the user via the menu directly in the display with simple button presses. Click here to see instructional video.

The units also have a presentation in percentage units for the current valve position directly in the display and via the digital communication. So, for example, if the control valve opens more under the same flow conditions, it may indicate blocked pipes or other potentially process-damaging conditions that need to be investigated.

Alicat BIO is also available with protection class IP66 as an option.

https://youtube.com/watch?v=4cDezbe154Q%3Ffeature%3Doembed%26enablejsapi%3D1%26origin%3Dhttps%3A

Posted by Jonas Lindgren at Kompauto Nordic AB and Kompauto Norway AS. jonas.lindgren@kompauto.com, Mob.+46 70 684 00 01

jonas.lindgren@kompauto.com, Mob.+46 70 684 00 01