Wastewater treatment processes are fundamental to municipalities of all sizes. These processes are complex and involve many points where water flow needs to be measured. High reliability and long-term stability are required to achieve a low operating cost. Pumping stations can be found in every municipal water and sewage treatment network. Flow measurement at such stations is a critical component for effective monitoring and control. Operations operators need detailed information from flow meters to monitor the flow to determine how the wastewater should be distributed to different treatment plants at different load periods. For example, when heavy rainfall causes the amount of stormwater to mix with the wastewater.

Typical challenges for operations

Since sewage networks and treatment plants need to be operated cost-effectively to ensure future investment needs, it is absolutely necessary that the operation is monitored and controlled. When heavy rains occur, wastewater levels in catch basins and wells can quickly reach critical levels. Therefore, accurate information from the flow measurement is needed to take appropriate measures in time.

When stormwater enters the sewage system, the purification processes become less efficient due to the increased load. Pumps run for a long time after a rain and have a large number of starts and stops, which in turn indicates that storm water has entered the sewage system and is about to be treated. The increased load costs money, money that is in short supply in the operating budget.

Reliable, uninterrupted operation is an important part of the sewage process. Municipalities with large residential and commercial areas cannot afford longer downtimes for maintenance, repairs or installation of new equipment.

The importance of flow measurement

Flow measurement of the water is a significant factor in the operation of the pumping stations. Accurate flow data helps operators understand if systems are running efficiently, where flow monitoring in pumping stations provides important reference points for billing processes, pump efficiency evaluation, analysis and maintenance program planning.

Traditionally, ultrasonic meters with Doppler technology have been used in pumping stations, but these flow meters do not provide sufficient measurement accuracy. In addition, the meters sit for a long time without maintenance, which means that the costs required to repair the existing meters become high.

Flow monitoring is the first step in identifying inflow to determine where problems are occurring and to isolate basins that cannot accommodate more. Therefore, instrument upgrade is necessary. Here are some of the main reasons for this:

- Eliminate flooding during both major and minor rainfall periods

- Get good analyzes of emission flow from each pump station

- Reduce costs for wastewater treatment

- Provide analytics to evaluate capacity for future major development projects

After evaluating the most common types of flow measurement based on known limitations, such as the inability to close station operations due to high loads with the difficulty of installing in-line flow meters in existing pipes, the most cost-effective option is flow meters with surface-mounted ultrasonic sensor

Although traditional inline meters, such as electromagnetic flow meters, provide high measurement accuracy, they require significantly more extensive planning and work to install in existing pipe systems. In addition, high IP classification is needed to cope with floods, etc. This cost, together with the associated excavation work, shutting off water and cutting pipes, drives up the project’s scope and total price.

Choose the right meter

After careful consideration of various manufacturers’ flowmeters, we have determined over the years that ultrasonic flowmeters with time-of-flight technology are the best option for pumping stations. Run-time flowmeters enable improved diagnostics to accurately measure flow, help identify potential pump failures and initiate preventive maintenance programs on station equipment, extending the life of all the different components in a pump station.

Flowmeters with sliding ice technology measure the flow rate by spreading ultrasonic waves into liquid-filled pipes and measuring the time the signal is transported through the water. With this technology, the meter is out of contact with the water providing benefits such as reduced installation costs, uninterrupted flow process, installation flexibility over a wide range of pipe sizes, no pressure drop and no moving parts to maintain. This approach allows for routine maintenance throughout the life of the meter without having to shut down the process to disassemble the instrument.

Kompauto Nordic AB, with its sister company Kompauto Norway AS, is a distributor for Badger Meter, an innovator in flow measurement and communication solutions serving water and wastewater treatment plants in municipalities worldwide. Badger Meter’s product range of Dynasonics® ultrasonic flow meters have been used for many years in water and wastewater applications globally.

Kompauto tillsammans med Badger Meter tillhandahåller produkter och kundsupport med hög kvalité och erfarenhet. Vårt mål är att installera fungerande, pålitliga flödesmätare vid var och en pumpstation hos kommuner i framför allt i Skandinavien.

Dynasonics TFX-5000 ultrasonic flowmeter is the latest solution for measuring volumetric flows containing pure liquids as well as liquids with small amounts of particles. Examples of this are stormwater and untreated sewage. The meter is available in a variety of configurations to meet specific application requirements. With integration into the PLC, users can be alerted to abnormal flow conditions and access a history of the most recent alarms, error and event codes. In addition, the flow meter supports a signal output for use with mobile transmitters for connection to the AquaCUE® cloud-based service and BEACON® for Advanced Meter Analysis (AMA). This software collects measurements at 15-minute intervals that are automatically uploaded to the cloud to help track and analyze water and wastewater flow information. A cloud service from Badger Meter that Kompauto provides free of charge when delivering flow meters.

Locally in the Flowmeter TFX-5000, data can also be read on a large, easy-to-read graphic display. It forwards data via analog 4-20mA signal, digital Modbus RTU, Modbus TCP/IP, BACnet MS/TP and BACnet/IP. Configuration and troubleshooting are done via a keypad or via a USB cable using the SoloCUE® Flow Device Manager software. The meter also has a four-level password security system for applications that require the blocking of unauthorized persons.

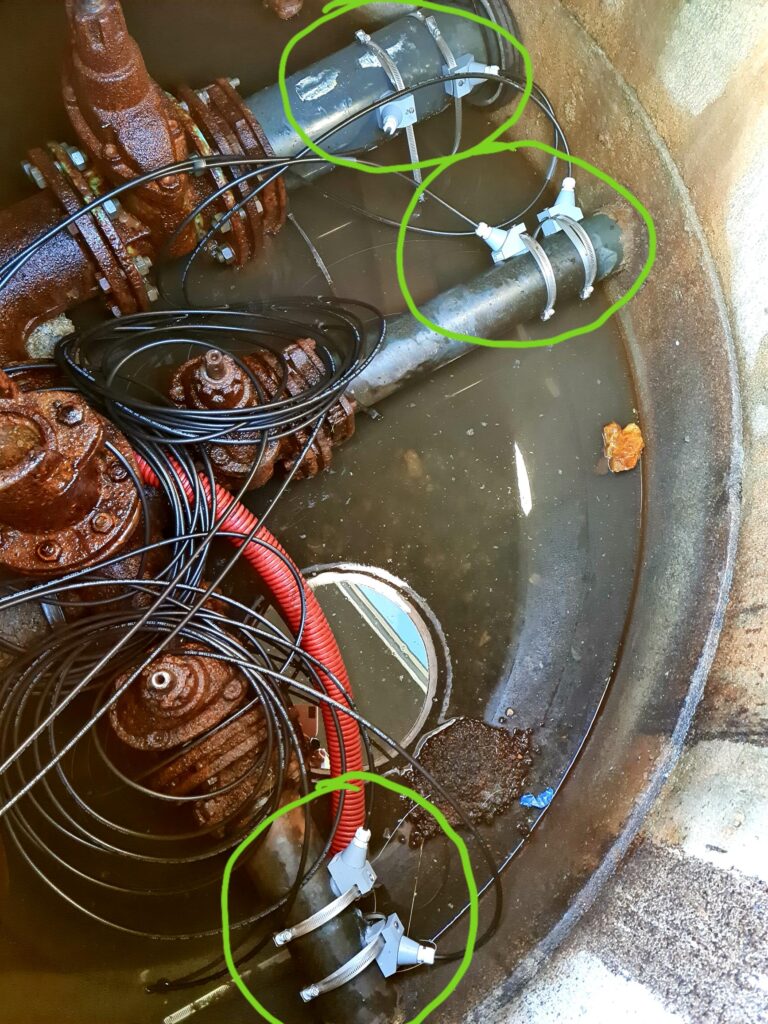

For outdoor installations below the surface of water, such as in measuring pits or wells, it is recommended that Dynasonic’s DTTN series submersible, IP68 rated sensors be used, greatly reducing the need for future maintenance.

In most municipalities, pumping stations are monitored via SCADA systems. The SCADA system data is continuously monitored to ensure the highest possible efficiency.

Dynasonic’s flow meter provides a 4-20 mA analog signal that is connected to a PLC in the pump station. The flows and data from other instruments are sent to the SCADA system where all data is trended and made available in the operator center where operators keep an eye on flow rates, pump run times and other operating parameters of the pump station.

Ultrasonic flow measurement provides data of flow for dry and wet weather directly from the pump stations so you can immediately see relevant information related to pump efficiency and leakage in lines between stations. By doing so, you can quickly detect operational disturbances that can over time lead to expensive and devastating consequences. The flow data makes it possible to calculate the existing capacity of pumping stations in order to then evaluate the capacity for possible new construction of commercial properties or residential construction in a specific area.

Advantages for sewer networks

Non-invasive flow meters like Dynasonic’s TFX-5000 are ideal when you can’t shut off your sewer flow to install a traditional inline meter. Because the ultrasonic meter measures on the outside of the pipe wall, no wear and tear occurs on the instrument, which makes it practically maintenance-free. The entire flow meter package consisting of ultrasonic sensor and transmitter can be easily installed by a single person. There is no need to cut pipes to install flow sensors and any by-pass lines via new valves etc.

Thanks to the use of clamp-on (external sensors), the TFX-5000 enables a very simple and cost-effective placement of flow measurement points either inside an existing pumping station, near pumps or as an independent measurement point for both wastewater and drinking water.

LEAKCELL® Plug & Play Flow Meter Station

Kompauto has listened to the market’s needs and developed the product LEAKCELL®, which is a complete Plug & Play package that, in addition to the flow meter, also contains a battery bank, solar panels for charging and a mobile transmitter for data transfer. LEAKCELL® is equipped with a mobile transmitter that sends flow data directly from the meter to the BEACON®/AquaCUE® web portal, which the user easily logs into via their computer browser or via a mobile app available in the Appstore and Google Play. In addition, LEAKCELL® can be delivered with a GSM Router that communicates directly with the user’s operation monitoring system via Modbus TCP/IP over a secure VPN connection. It is compatible with virtually all operation monitoring systems on the market, regardless of whether it is, for example, Guard, Cactus, OneCo, ABB or others.

The complete flow meter package is adapted to the customers’ needs in terms of power supply, communication method, number of measuring points, etc. In addition, LEAKCELL® can also be supplemented with other types of measuring sensors. Examples of this are level measurement, pressure measurement and analysis of the water.