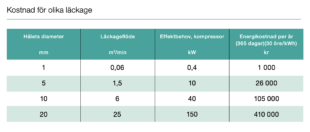

In a modern compressed air system, parameters such as flow, dew point, pressure and air quality are continuously monitored. Measuring the flow is to ensure that the compressor is working as it should and that leaks in the compressed air network should be detected at an early stage. Leakage costs a lot both in terms of environmental impact and in money with increased energy consumption from the compressors and that it generates increased maintenance costs because the compressors and other peripheral equipment then have to work completely unnecessarily. You can compare it to picking up the car at night, starting the engine and putting it in gear so that it "rolls" a lot of extra miles and consumes extra fuel completely unnecessarily. The table below shows what each leakage point costs on average in energy consumption for the compressor (Source: The brochure "Use energy more efficiently in your company" from the Energy Agency)

Changing filter inserts in your compressed air system too infrequently is also a big energy culprit because an increased differential pressure across filters generates increased energy consumption for the compressors. This can be easily remedied by measuring pressure before and after the filter pack, where you get an alarm signal when the differential pressure exceeds a given level, which indicates that the filter inserts must be changed.

For many years, Kompauto has developed sustainable solutions to create efficiency in compressed air systems. We provide our expertise in this area to develop the most effective solution possible to our customers' unique needs.

We help you with which measurement points are interesting to measure in order to create as much efficiency as possible in your particular compressed air network. Depending on the size and type of process to be monitored, we develop customized solutions within Flow measurement, Dew point measurement, Pressure measurement and leak detection in your compressed air system.